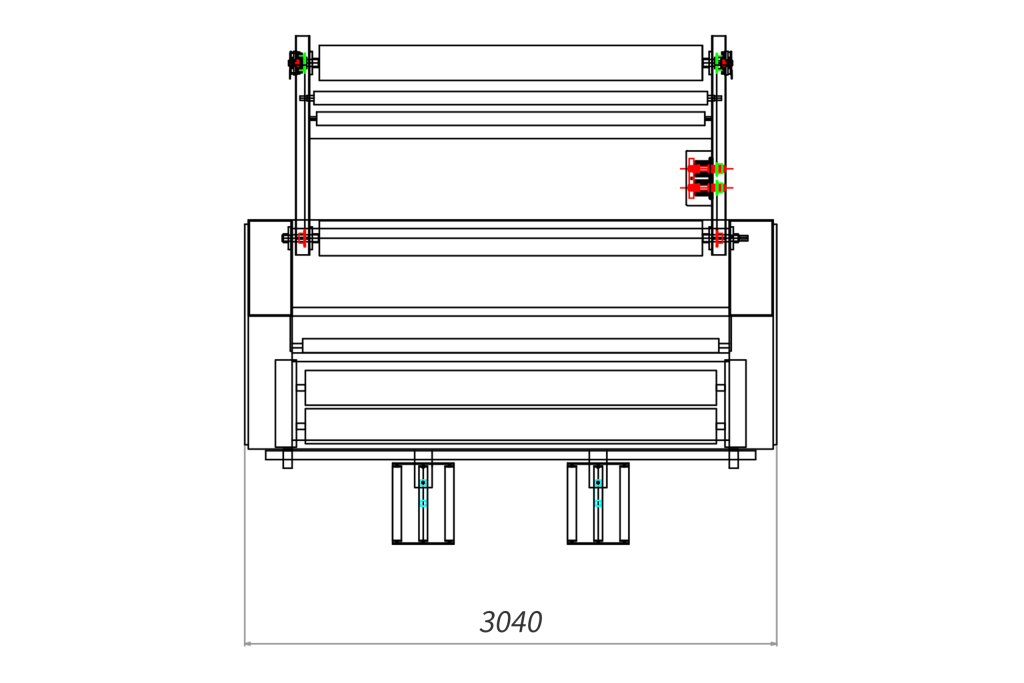

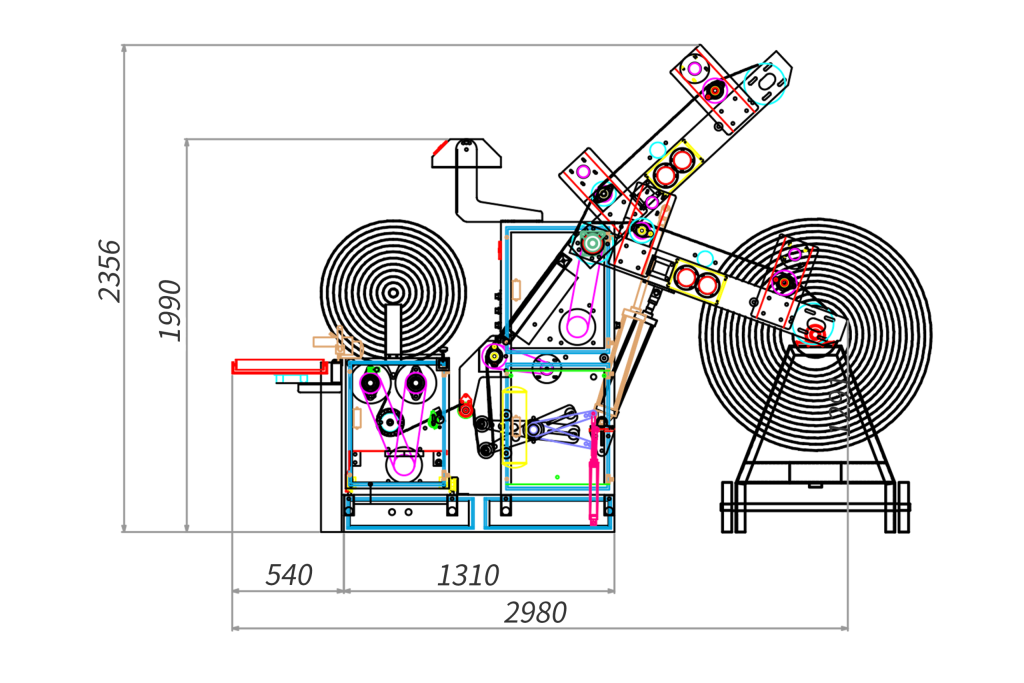

FK-A Frame Unwinding & Winding Machine

Depth 2980mm |Width 3040mm | Height 2356mm

This advanced textile machinery is equipped with a 750W motor coupled with a worm gear-driven anti-slip silicone roller, ensuring precise fabric handling. The system features a dual-cylinder constant pressure lifting mechanism for stable operation and incorporates an emergency stop function with instant A-frame braking for safety.

Inverter Speed Control

Digital Communication Meter

Pneumatic Pressure Regulation

Dual Edge Detection System

Silicone-coated Winding Roller

Dancer Roll Assembly

Fabric Expander

Hydraulic Edge Guide

Independent AC Drive Motors

Dual silicone-coated winding rollers with dedicated servo motors and inverters

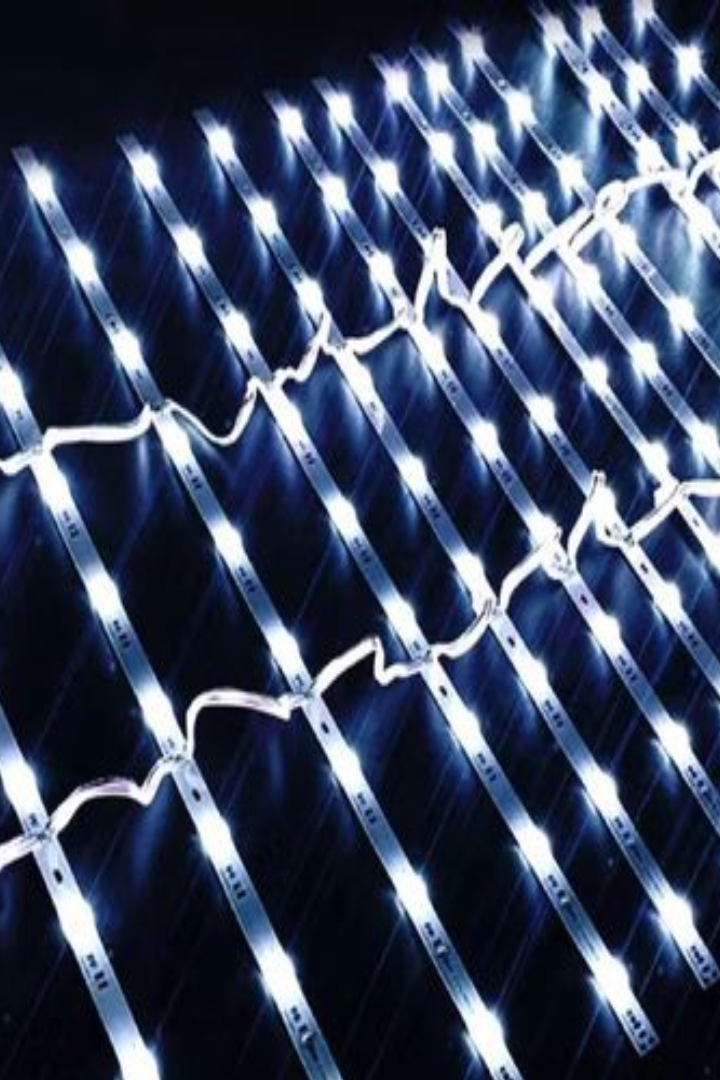

Starlight LED Illumination

Dimmable LED array with diffuse reflection backlight panel

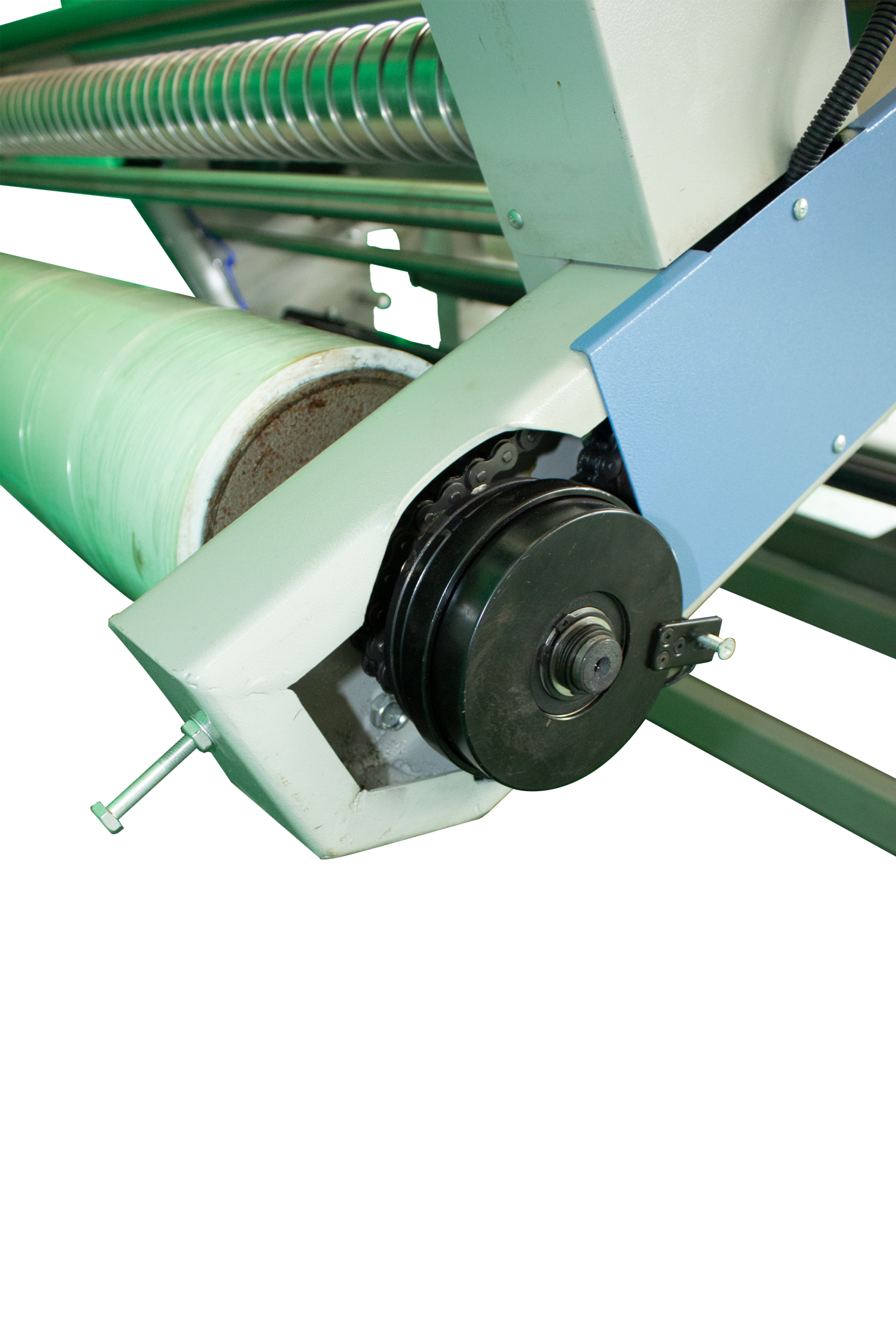

Electromagnetic Clutch

Independent roller rotation control with fail-safe mechanism

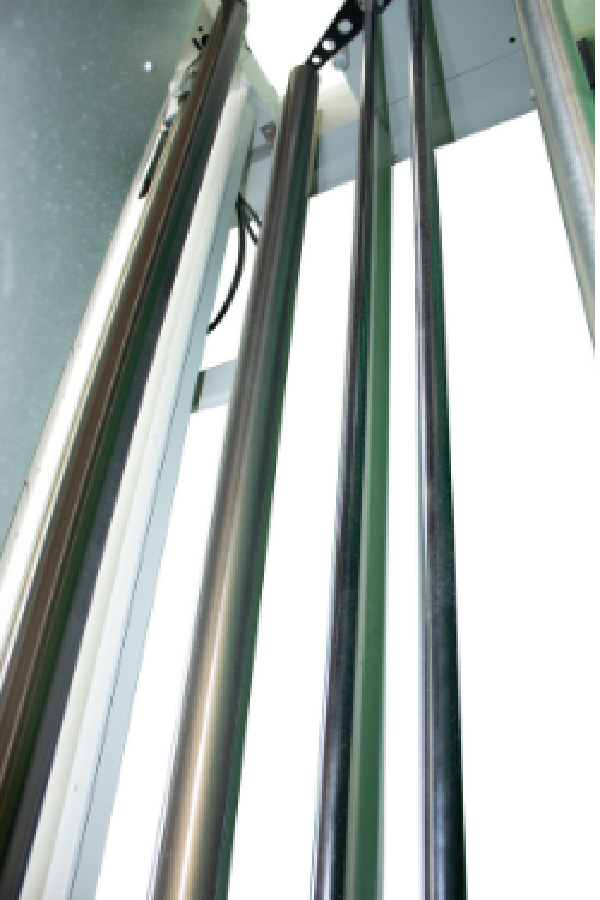

Top Silicone Roller Assembly

Top-mounted Wear-resistant Anti-slip Silicone Roller above Light Box

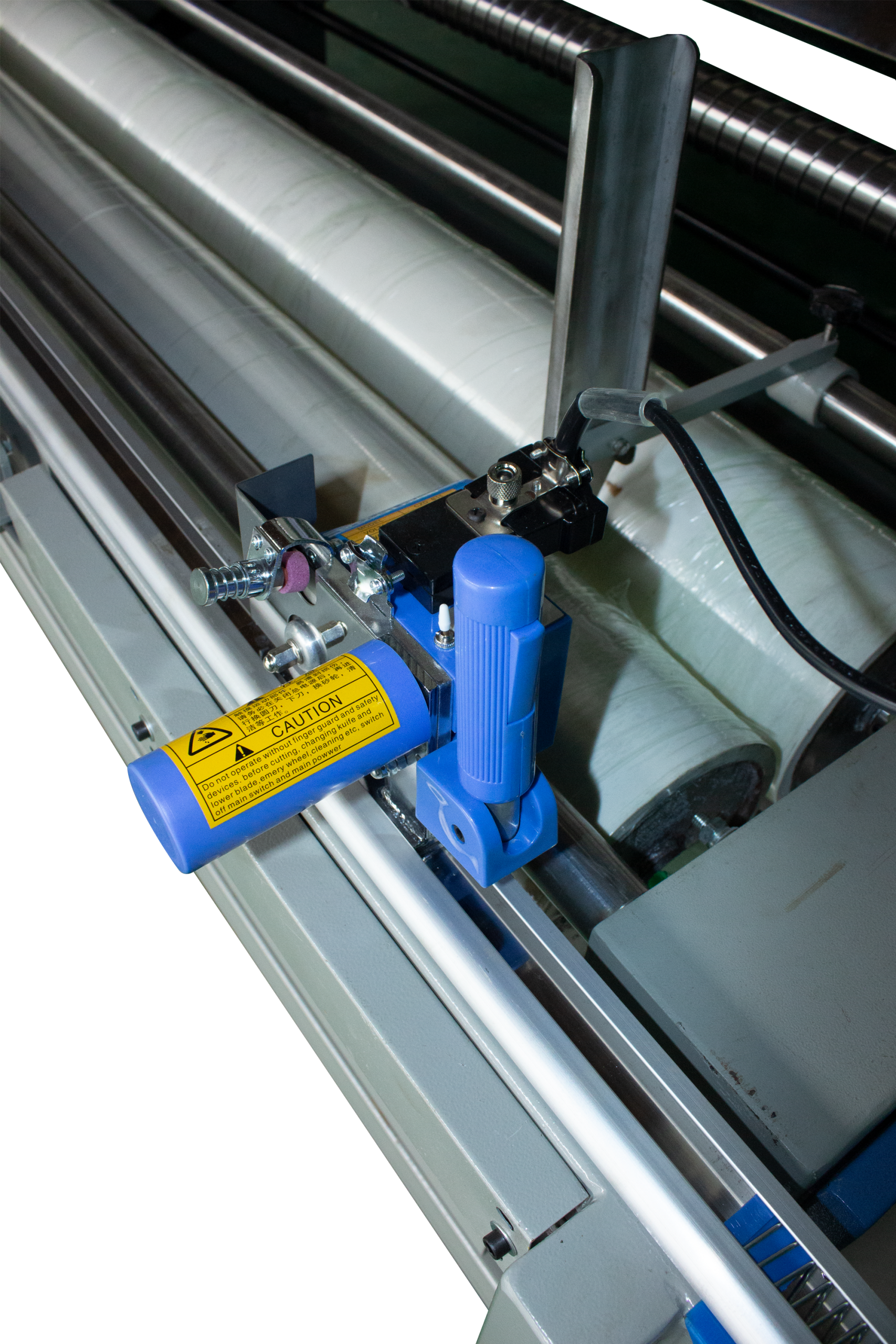

Rail-guided Circular Cutter

250W/220V rotary blade with integrated sharpening stone

Auto-guided Fabric Cutter

Stepper-driven brushless motor (250W/220V) with linear rail system

Integrated Weighing Platform

100kg capacity load cell with 50g resolution

2.2kW Three-phase Asynchronous Motor

High-torque induction motor

Machine Specifications

Operating Voltage

380V E*E (A. B. C. N. PE) /50HZ/3kw

Top Roller

φ114mm rough-surface rubber roller

Main Roller

φ160mm Wear-Resistant Silicone Roller / φ160mm Stainless Steel Roller

Dual Frequency Conversion Speed Regulation

1.5kW Closed-Loop Vector Frequency Drive; Adjustable Tension

Machine Speed

0-100m/min; Acceleration Time 5 sec; Deceleration Time 3 sec

Electronic Length Counter

Meter/Yard switchable;Auto-stop at preset length;Power-off memory;RS485 communication

Automatic Error Correction

2.5mm Aluminum Alloy Photoelectric Sensor/380mm StrokeHydraulic Transmission

Working Width

190/230/320/360CM Custom widths available

Button-Adjustment Zone

Left/Right

Controls winding hydraulic trolley movement in manual edge alignment mode

Edge Alignment – Manual/Auto

Toggles edge alignment mode (auto alignment disabled during reverse)

Power – On/Off

Main power switch

Opening – On/Off

Controls wire expander roller under inspection table

Backlight – On/Off

Inspection backlight panel control

Tension

Adjusts fabric roll tightness

Button – Inspection Table

Host Speed – Fast/Slow

Adjusts machine running speed

Host – Reverse/Forward

Switches between winding/unwinding modes

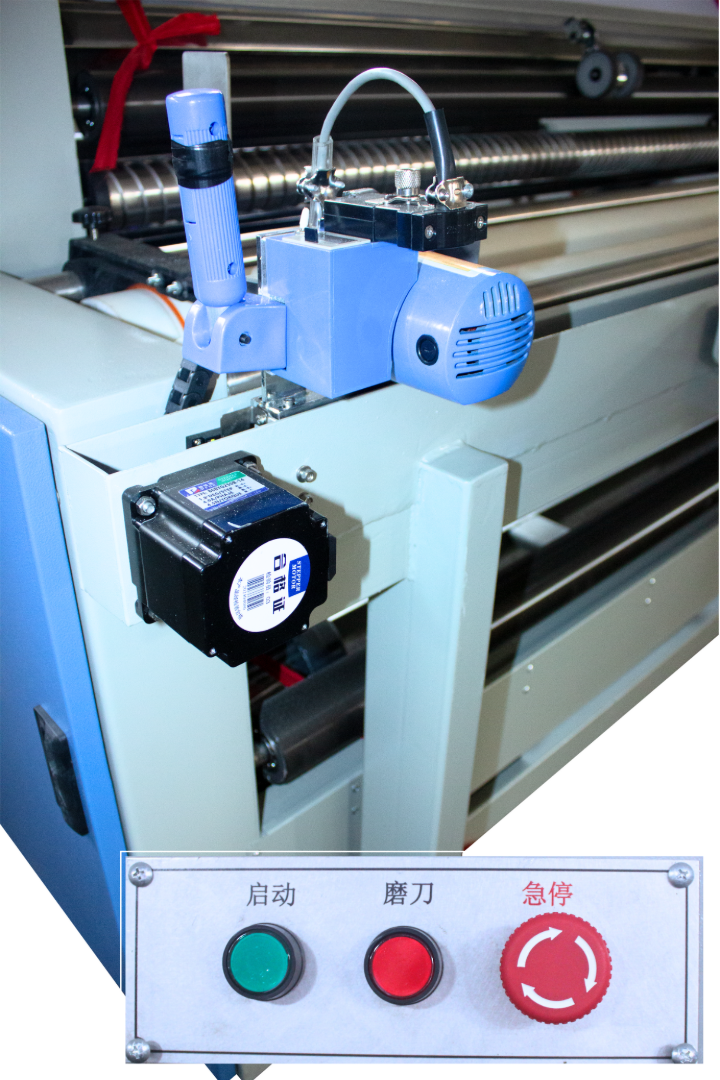

Host On

Enables motor for speed adjustment

Host Off

Disables motor with brake shutdown

Contact Us

0512-63599187

Address: East Side of Xiaoping Avenue, Badu, Zhenze Town, Wujiang District, Suzhou City, Jiangsu Province, China