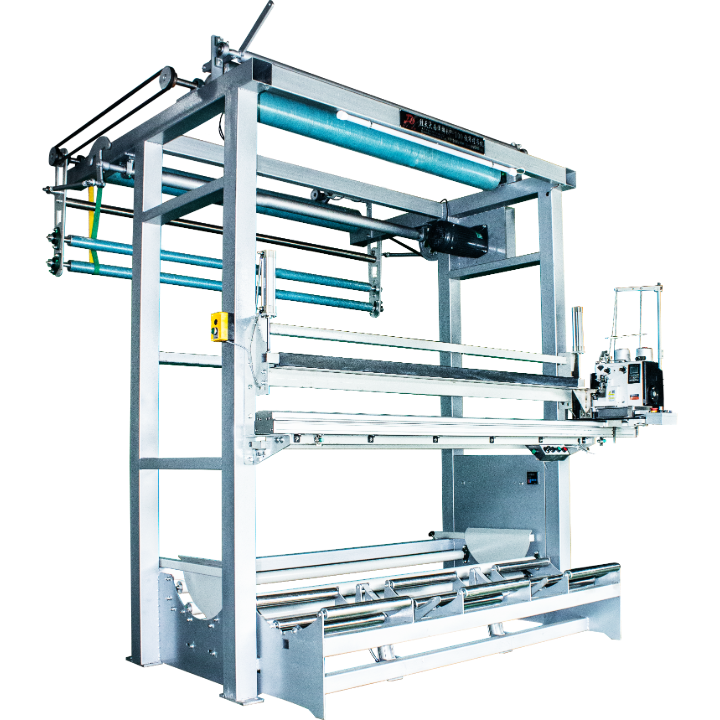

BF-100-Cloth Feeding & Spreading Machine

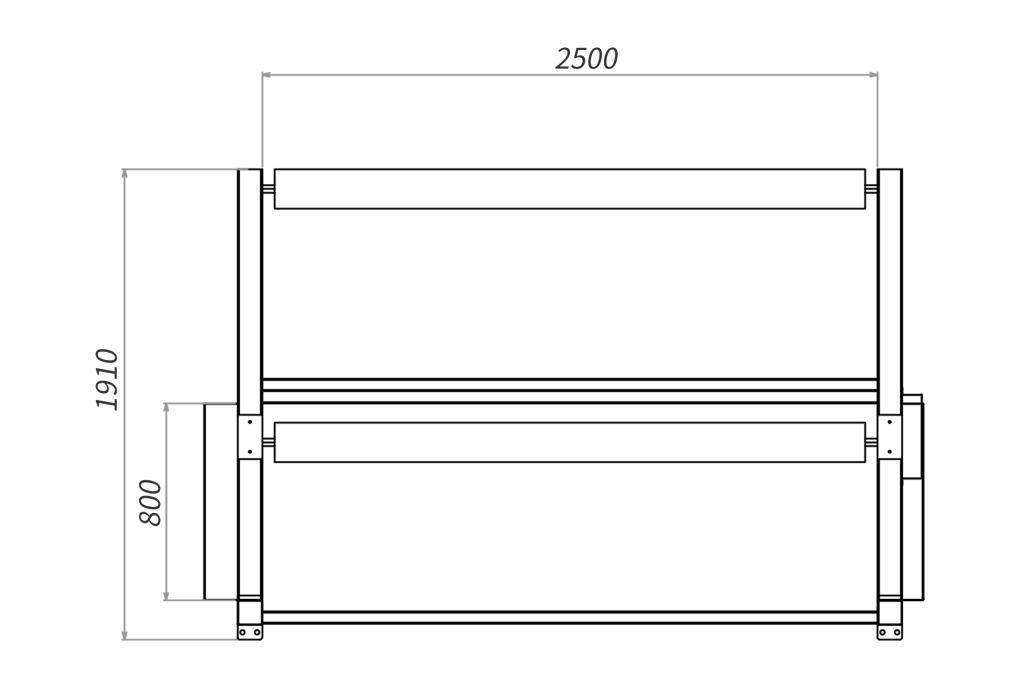

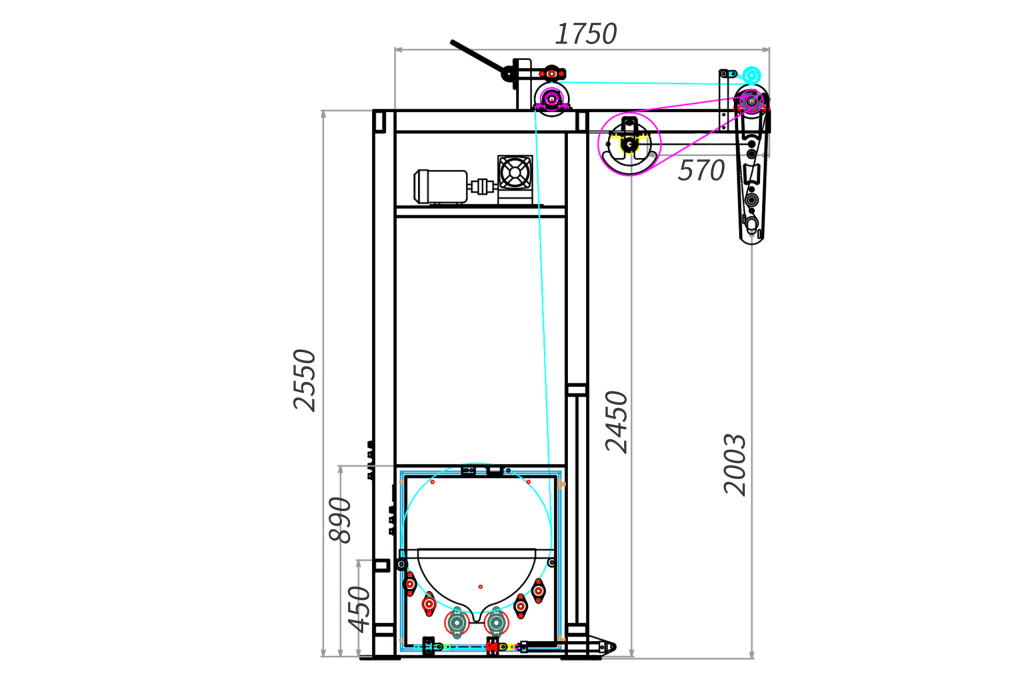

Depth 1910mm | Width 2550mm | Height 2550mm

The machine boasts a robust welded construction with built-in guide rails and expansion bolt fastening, delivering stable performance even during high-speed unwinding. Featuring motorized hooks for one-touch roll flipping, it automatically transfers fabric rolls to the unloading trough and stops when fabric runs out. The integrated overlock sewing machine neatly joins fabric ends while the pneumatic press bar prevents weft distortion, with automatic scrap trimming for efficient operation. Designed for user-friendly operation and material savings, it handles fabrics of all thicknesses with ease.

Full Welding Process

Unwinding Trough

Pneumatic Flipping Bucket

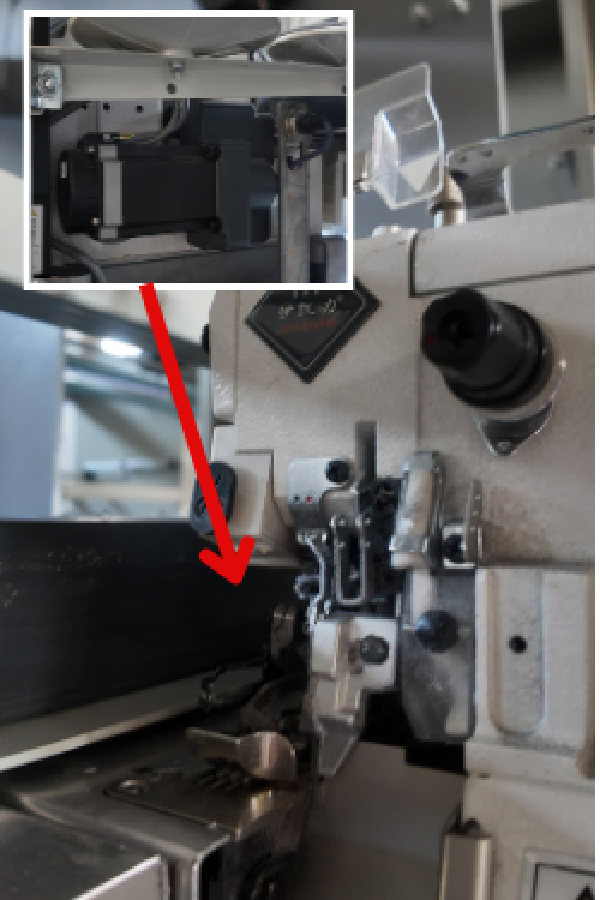

2-Thread Overlock Sewing Machine

Linear Slide Module

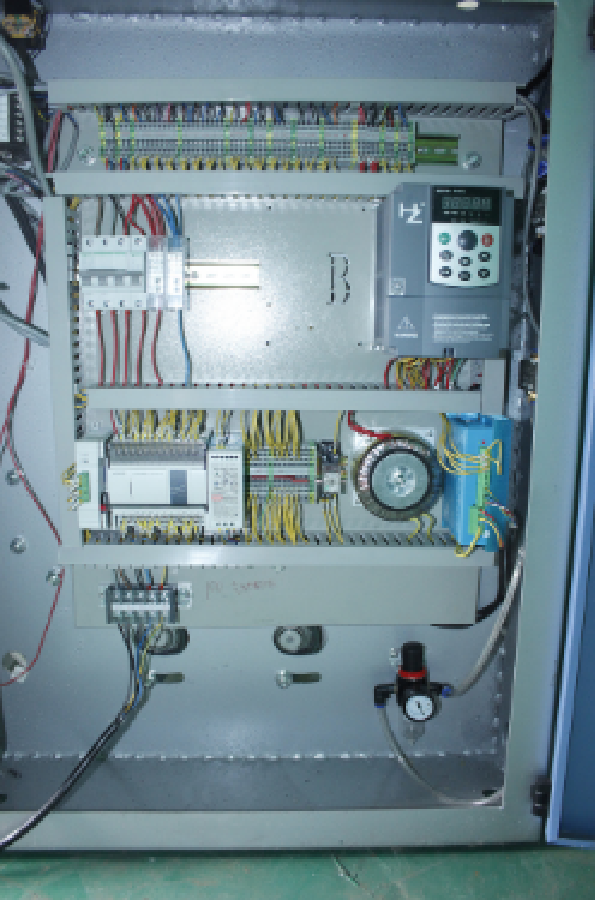

Variable Frequency Speed Control

Stepper Motor Presser Foot Lift

Machine Specifications

Operating Voltage

380V E*E (A. B. C. N. PE) /50HZ/3kw

Top Roller

φ114mm rough-surface rubber roller

Air Pressure

Air Pressure: ≥0.7MPa;Air Consumption: ≥40L/min

Variable Frequency Drive

1.5kW closed-loop vector control

Machine Speed

0-100m/min

Electronic Length Counter

Meter/Yard switchable;Auto-stop at preset length;Power-off memory;RS485 communication

Sewing Head Configuration

2-Thread Overlock Sewing Machine;Stepper motor-driven presser foot lift;Direct-drive, energy-saving, low-noise;Automatic thread trimming;Presser foot lift height: up to 10mm

Working Width

230/360CM Custom widths available

Buttons – Adjustment Zone

Power-0/1

Main power switch (ON/OFF)

Speed Adjustment-Fast/Slow

Adjusts machine running speed

Main Unit – Fwd/Rev

Switches between winding and unwinding modes

Main Unit ON

Enables motor drive (allows speed adjustment)

Main Unit OFF

Disables motor drive (activates braking stop)

Buttons – Sewing Head Controls

Emergency Stop

Immediate sewing head shutdown

Pneumatic Clamp

Activates fabric press bar

Reset

Returns sewing head to home position

Start

Initiates seam stitching cycle

Retract

Sewing head reverse movement

Advance

Sewing head forward movement

Contact Us

0512-63599187

Address: East Side of Xiaoping Avenue, Badu, Zhenze Town, Wujiang District, Suzhou City, Jiangsu Province, China