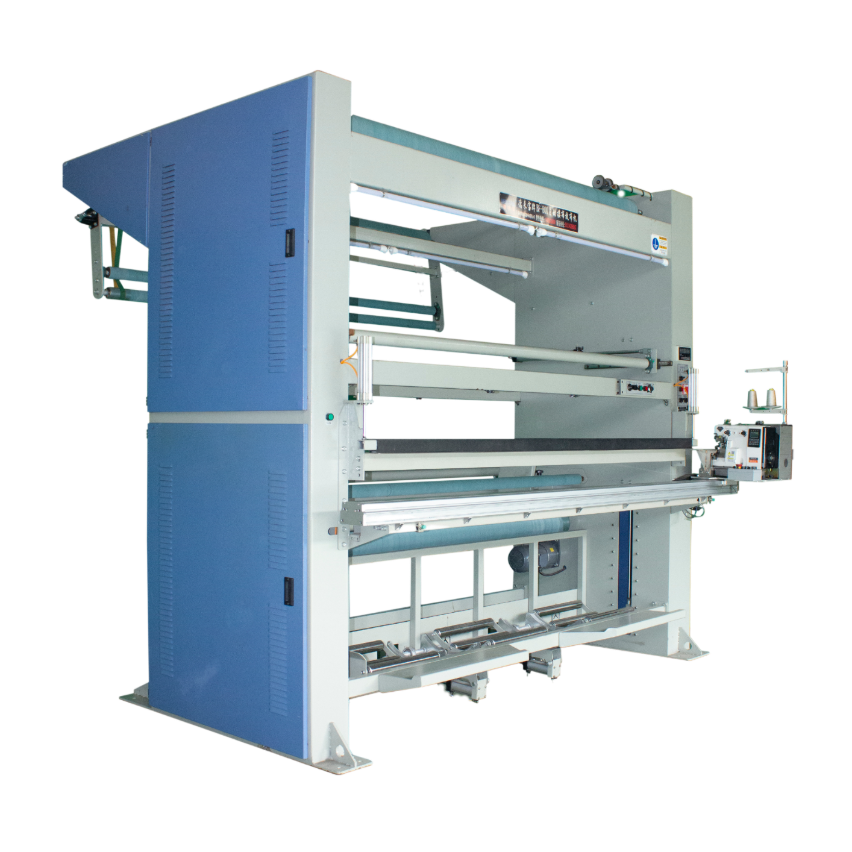

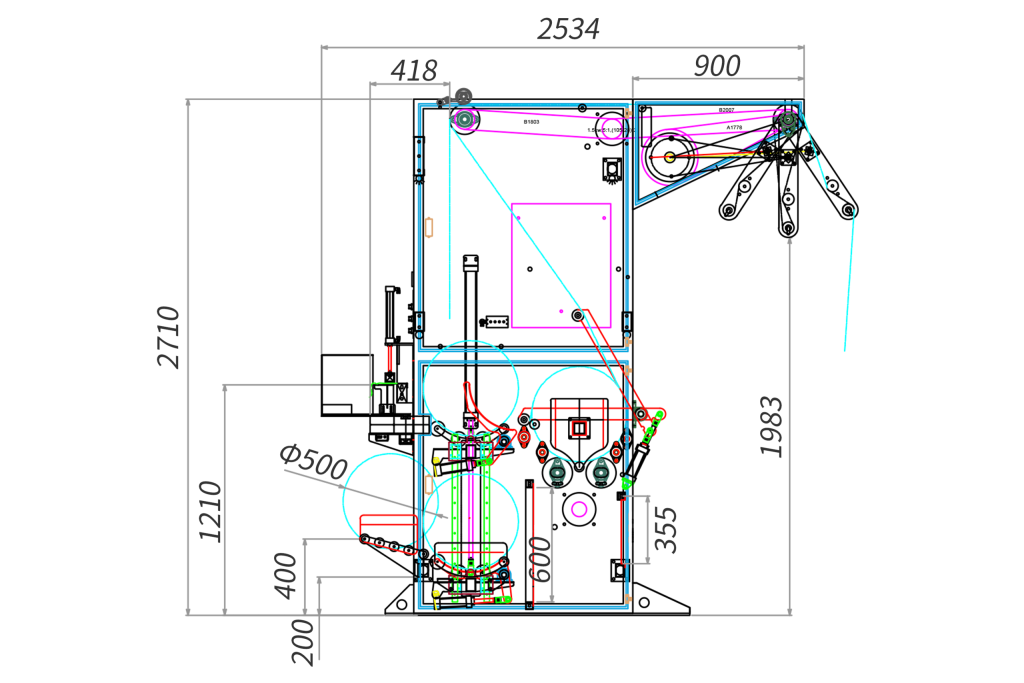

BF-800-Cloth Feeding & Spreading Machine

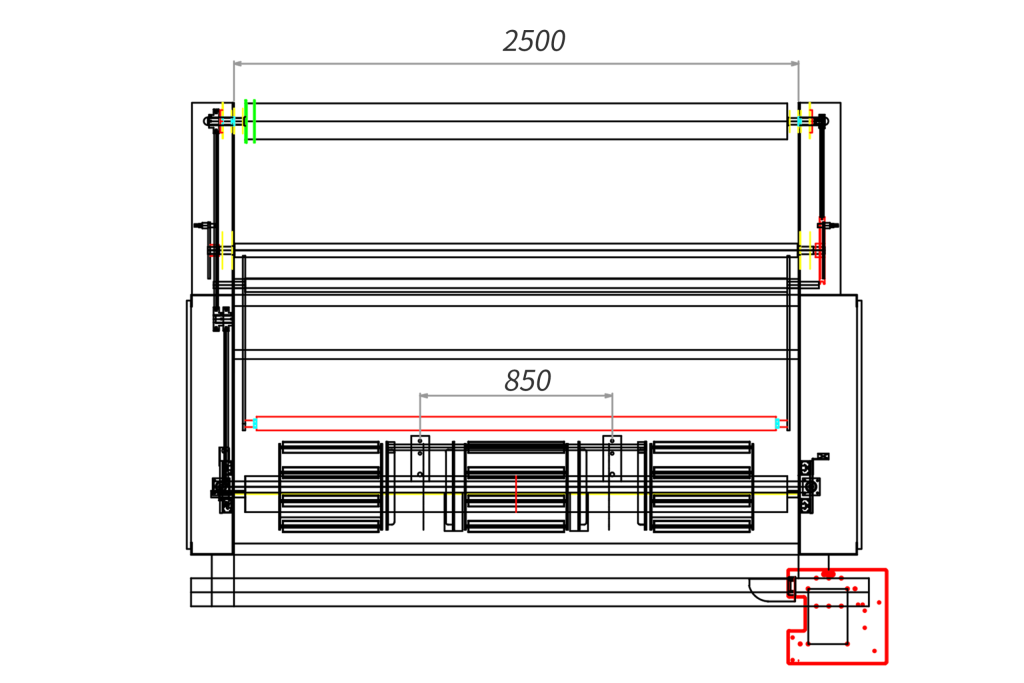

Depth 2534mm | Width 2500mm | Height 2710mm

The machine features a fully-welded frame with integrated linear guides and expansion bolt anchoring, delivering vibration-free operation at high speeds. Its motorized roll-flipping system enables one-touch operation, while the servo-controlled constant tension system and adaptive speed regulation significantly enhance productivity. Equipped with automatic core tube feeding and fabric-end retention at stoppage, it handles all fabric types (woven/knitted/nonwoven) with specialized overlock stitching that eliminates fiber shedding. The system supports seamless integration with ERP systems to meet smart manufacturing management requirements.

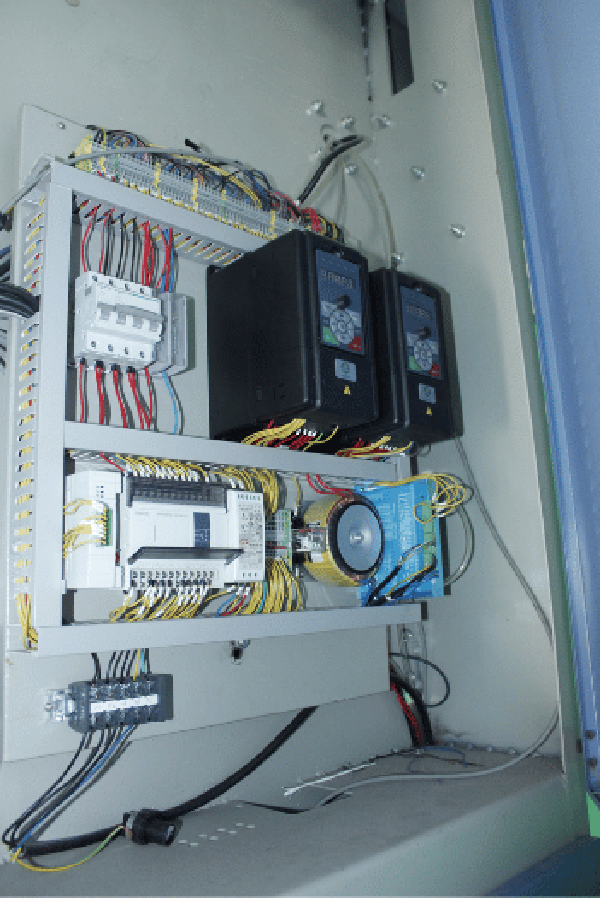

Variable Frequency Speed Control System

Unwinding Trough

Pneumatic Flipping Bucket / Auto Fabric Turner

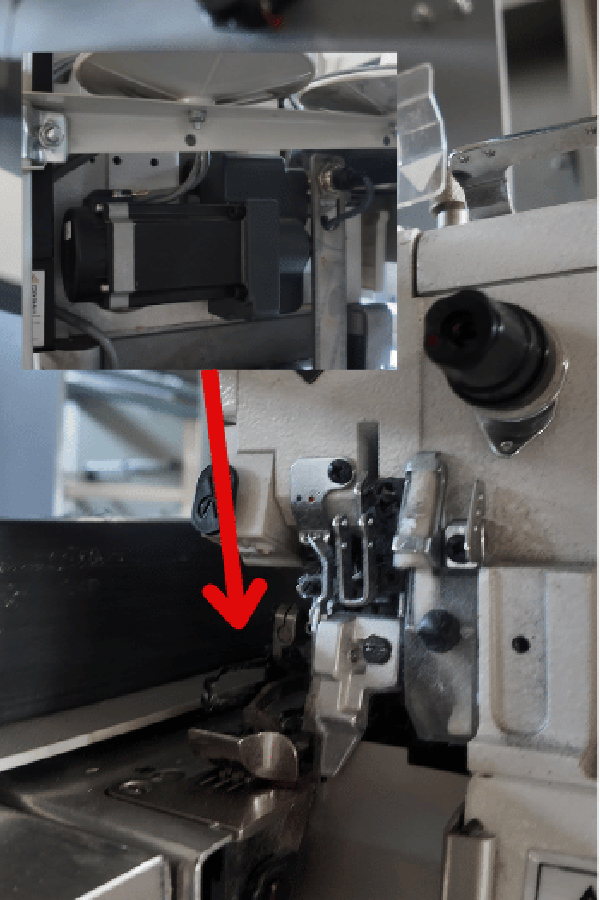

High-Power Sewing Head

Stepper Motor Presser Foot Lift

Linear Slide Module

Machine Specifications

Operating Voltage

380V E*E (A. B. C. N. PE) /50HZ/3kw

Top Roller

φ114mm rough-surface rubber roller

Air Pressure

Air Pressure: ≥0.7MPa;Air Consumption: ≥40L/min

Variable Frequency Drive

1.5kW closed-loop vector control

Machine Speed

0-100m/min

Electronic Length Counter

Meter/Yard switchable;Auto-stop at preset length;Power-off memory;RS485 communication

Sewing Head Configuration

2-Thread Overlock Sewing Machine;Stepper motor-driven presser foot lift;Direct-drive, energy-saving, low-noise;Automatic thread trimming;Presser foot lift height: up to 10mm

Working Width

230/360CM Custom widths available

Buttons – Adjustment Zone

Light ON/OFF

Main lighting control

Power-0/1

Main power switch

Manual Flip Fabric

Manually flips fabric into unwinding trough

Sync Unwinding ON/OFF

Enables/disables synchronized unwinding

Unwinding Direction (Fwd/Rev)

Controls unwinding rotation direction

Auto/Manual Mode

Toggles between auto & manual flipping

Lift/Lower

Raises/lowers flipping mechanism manually

Buttons – Operation Zone

Speed Adjustment (Fast/Slow)

Adjusts machine speed via rotary encoder

Main Unit (Fwd/Rev)

Switches motor rotation direction

Motor ON

Enables motor drive

Motor OFF

Cuts motor power (brake activated)

Tension Adjustment (Loose/Tight)

Adjusts unwinding tension

Buttons – Sewing Head Controls

Emergency Stop

Immediate sewing head shutdown

Pneumatic Clamp

Activates fabric press bar

Reset

Returns sewing head to home position

Start

Initiates seam stitching cycle

Retract

Sewing head reverse movement

Advance

Sewing head forward movement

Contact Us

0512-63599187

Address: East Side of Xiaoping Avenue, Badu, Zhenze Town, Wujiang District, Suzhou City, Jiangsu Province, China