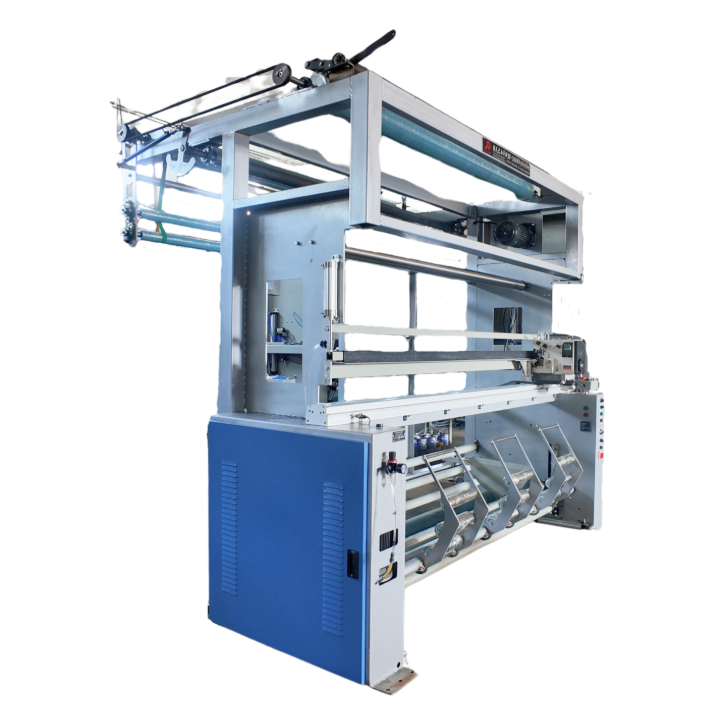

BF-300-Cloth Feeding & Spreading Machine

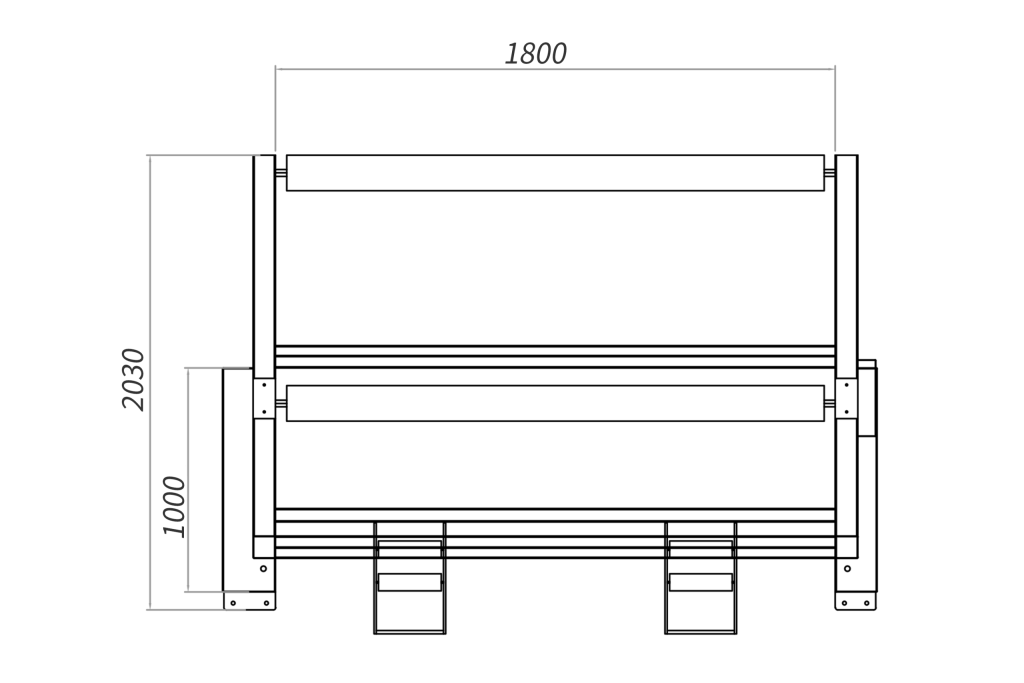

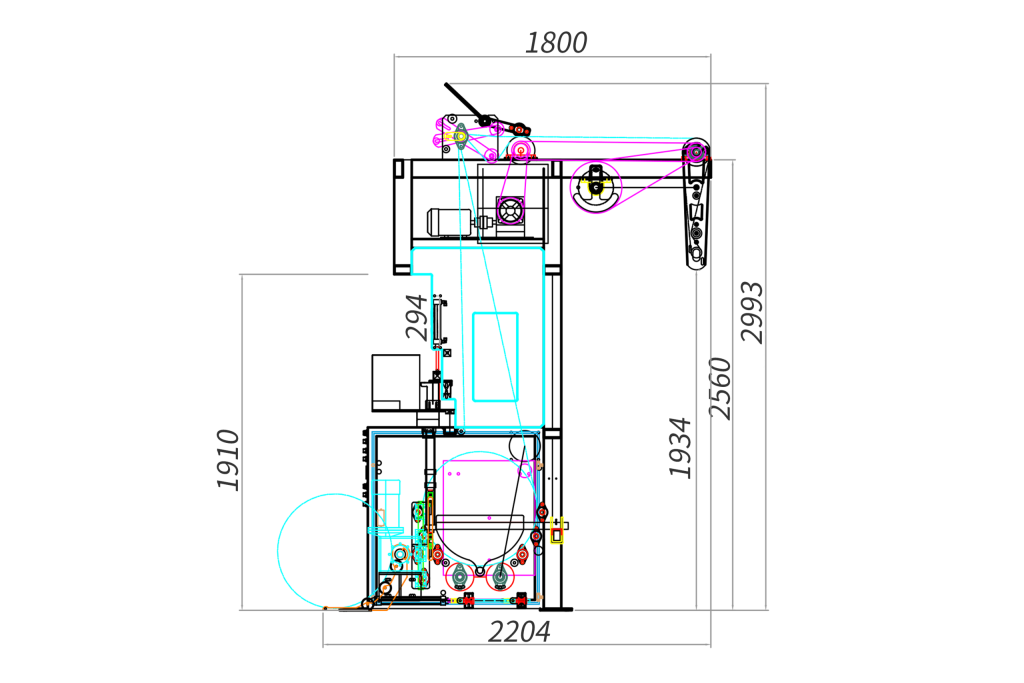

Depth 2030mm | Width 1800mm |Height 2993mm

The machine features a fully-welded frame with integrated linear guides and expansion bolt anchoring, delivering vibration-free operation at high speeds. Its motorized roll-flipping system enables one-touch operation, while the servo-controlled constant tension system and adaptive speed regulation significantly enhance productivity. Equipped with automatic core tube feeding and fabric-end retention at stoppage, it handles all fabric types (woven/knitted/nonwoven) with specialized overlock stitching that eliminates fiber shedding. The system supports seamless integration with ERP systems to meet smart manufacturing management requirements.

Synchronized Unwinding Trough

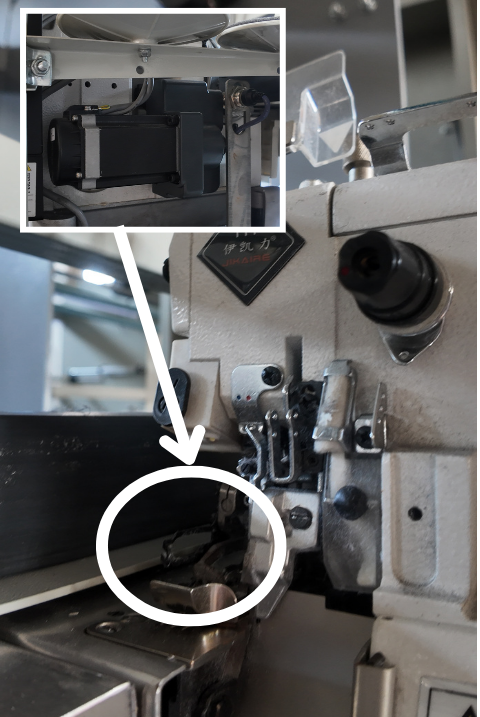

Stepper Motor Presser Foot Lift

2-Thread Overlock Sewing Machine

Galvanized Pipe Tension Frame

Dual-frequency Inverter Drive

Embedded Architecture

Motorized Flipping Bucket

Sealed Linear Slide Module

Machine Specifications

Operating Voltage

380V E*E (A. B. C. N. PE) /50HZ/3kw

Air Pressure

≥0.7MPa;Air Consumption≥40L/min

Roller Configuration

Top Roller:φ114mm rough-surface winding roller;Unwinding Main Roller:φ160mm rough-surface roller

Dual-Frequency Inverter Drive

1.5kW closed-loop vector control

Machine Speed

0-100m/min (Acceleration: 5s | Deceleration: 3s)

Electronic Length Counter

Meter/Yard switchable;Auto-stop at preset length;Power-off memory;RS485 communication

Tension System

Self-Balancing Tension Frame (Galvanized Pipe);PID Control

Working Width

230/360CMCustom widths available

Contact Us

0512-63599187

Address: East Side of Xiaoping Avenue, Badu, Zhenze Town, Wujiang District, Suzhou City, Jiangsu Province, China